High efficiency is crucial

Jonas Moberg is technically responsible for the development of new vessels at Gotlandsbolaget and is one of several people driving the Gotland Horizon project forward. In this interview, Jonas answers some common technical questions about the shipping of the future and the importance of high efficiency to make the shift to a fossil-free crossing.

/https%3A%2F%2Fgotlandsbolaget.se%2Fwp-content%2Fuploads%2F2022%2F04%2FJonas.jpg)

How is the Gotland Horizon progressing?

The design of the Gotland Horizon is based on our desire to be able to continue to offer a short crossing time without negatively impacting the environment. We need to ensure a relatively high speed and clean fuel, with as little energy demand as possible. Minimizing energy demand requires an energy-efficient design and high efficiency. Therefore, we develop energy-efficient hulls, minimize weight, review energy consumers and streamline operations and flows throughout the ship.

We have a close dialog and work with several different suppliers and developers of equipment for Gotland Horizon. Two important aspects we are looking at in particular are that the gas turbines should be able to run on 100 percent hydrogen, and here the development is far ahead and we see new progress all the time. The second aspect is about ensuring access to and infrastructure for hydrogen and we have several projects underway, including with Uppsala University to secure hydrogen for traffic by 2030.

Why should the ship be powered by a gas turbine?

For different modes of transport and transport needs, the choice of technology is very different. Electric motors combined with fuel cells, traditional piston engines or gas and liquid fuel turbines are some examples that are often discussed. Different companies will find solutions that work best for them. For short distances with low energy demand, batteries may be suitable if electricity generation is clean, for areas without liquid gas infrastructure, liquid fuels may be preferable, hydrogen requires large volumes or extreme cold and is difficult to transport and will be suitable if available close to the consumer.

The gas turbine is often perceived as energy-intensive, but in combination with a steam turbine we achieve an efficiency that is equivalent to, or even higher than, a diesel engine. This means that the gas turbine in conjunction with the steam turbine in a so-called ‘combined cycle’ has several advantages for Gotland traffic and similar shipping needs. With this, we can maintain the same speed as today while running on 100% fossil-free gas. Most other technology choices lack this feature.

In addition, the gas turbine provides a better working environment with lower vibrations and less spillage, which otherwise occurs with oil-based fuels in the engine room.

What is meant by combined cycle?

Combined cycle means that we combine the gas turbines with a steam turbine. The steam turbine harnesses the residual energy from the gas turbine and generates electricity to help propel the ship. Together, we create a power plant on the ship that increases the efficiency from around 30% (gas turbine only) to 50%.

Will the ship run on 100% hydrogen?

The ambition is of course for the Gotland Horizon to run on hydrogen alone, but this is dependent on there also being a large supply. Thanks to the great fuel flexibility of our design, it is also possible to run on other fuel types, which would also allow for a mix of different gases or fuel types. For example, biogas and hydrogen would be a good combination.

Are there any disadvantages or challenges in choosing hydrogen?

At present, there are no large-scale hydrogen production facilities, which of course begs the question – will the ship be able to be supplied with hydrogen? But right now there are many different projects underway that look at just this. Among other things, the project led by Uppsala University where we are involved in developing and evaluating system solutions for using hydrogen produced with fossil-free electricity via electrolysis as fuel in a large-scale system for Gotland ferry traffic.

In addition to production, large-scale hydrogen fuel handling needs to be developed. At the moment, there is a lack of production of certain components that are needed.

What’s the best thing about Gotland Horizons technology?

One of the best things about the way we developed Gotland Horizon is that the vessel has extremely high fuel flexibility. There is still a lot of uncertainty about what the fuel supply will look like in different markets, so we have to be prepared for different options and flexible for different solutions. The Gotland Horizon is designed for hydrogen but can run on multifuel, i.e. she can run on several different fuels, both liquid and gaseous. This gives the ship a good future assurance to be able to drive the transition regardless of the availability of the fuel market.

What is the next step in the project?

As we have previously discussed, fuel management is an important issue that involves major and crucial choices. Here, intensive work is underway to develop a basis and ensure production, access and the right infrastructure of fuel.

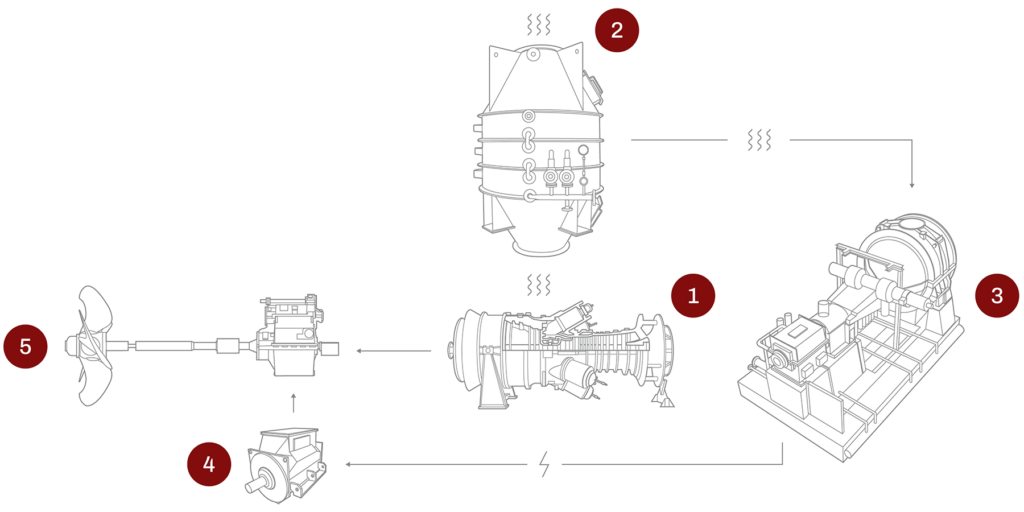

Gotland Horizons technology in brief

1. the gas turbine is powered by hydrogen and has a mechanical drive train to the ship’s gearbox

2. The hot gas from the gas turbine is passed through a steam boiler to create water vapor in the stack

3. The water vapor in turn drives a steam turbine that is connected to a generator to produce electricity

4. The electricity drives an electric motor, which also connects to the same gear system that drives the gas turbine

5. The combination becomes an electric and mechanical drivetrain that is both flexible and efficient